World-class Innovation

Air Products pioneered the “on-site” concept of producing and selling industrial gases in 1940. That revolutionary idea not only launched our company, it launched the industrial gas industry we know today.

Since then, we have built a reputation for our innovative culture, operational excellence, and commitment to safety and the environment. Tomorrow’s challenges demand diverse thinking, applications and mega-project expertise, and a collaborative spirit. Our passionate and talented employees are rising to this challenge every day by creating innovative solutions that benefit our customers and our world.

INDUSTRY – LEADING TECHNOLOGIES

Leader in hydrogen fueling infrastructure and leading developer of hydrogen energy services and equipment.

Global leader of technical options for capturing CO₂ from fossil fuel conversion before it reaches the atmosphere, key to Carbon Capture and Sequestration.

Premier provider of turnkey solutions to convert hydrocarbon feedstock into synthesis gas for high-value products.

Pioneer in gas membrane separation for commercial use with early projects commissioned in 1977 and full-scale commercialization in 1979.

Rotoflow is both a pioneer and leader in turboexpander technology for the hydrocarbon, LNG, petrochemical, and industrial gas markets.

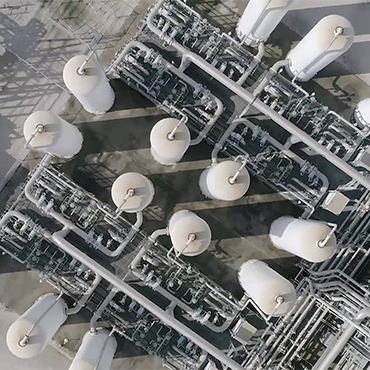

Pioneer in air separation technology with unparalleled experience in designing, engineering, constructing and operating cost-effective gas supply systems.

Leading provider of carbon monoxide and syngas supply and technology solutions.

The world’s future depends on low- and zero-carbon solutions. Air Products’ hydrogen is key to accelerating the energy transition.

80+ Years of Differentiated Innovation

Our Applications Technology teams around the world focus on new value

creation for our customers through innovative and sustainable offerings that

help them improve the productivity, quality and safety of their processes, while

reducing their costs and environmental impact.

Cryogenic Food Processing

Our Freshline® cryogenic tunnel freezers and injection systems use the rapid cooling power of nitrogen and carbon dioxide to provide food processors with efficient, hygienic, reliable and cost-effective freezing and chilling solutions.

Oxy-fuel Combustion

Our Freshline® cryogenic tunnel freezers and injection systems use the rapid cooling power of nitrogen and carbon dioxide to provide food processors with efficient, hygienic, reliable and cost-effective freezing and chilling solutions.

Heat Treating

Our innovative gas density sensor allows reliable, low-cost monitoring of customers’ furnace atmospheres in various heat treating processes.

Innovative Solutions for Reliable Helium Supply

Air Products is continually innovating new solutions to keep our customers’ operations running with a dependable supply of helium. Our helium storage salt cavern in Beaumont, Texas is the world’s largest—roughly the size of the Empire State Building—located thousands of feet below ground.

In addition, our one-of-a-kind helium production facility located in Doe Canyon, Colorado uses cutting edge technology, combined with world-class operations, to extract and produce helium.

The helium from these facilities strengthens and diversifies our helium supply chain to further enable the reliable delivery of product to our customers around the world.

Our Digital Strategy

The innovative use of data and technology is fundamental to our long-term

competitiveness. We use them as an engine to drive safety, simplicity, speed

and self-confidence, and to achieve our company goals. Here are just a few

examples of how we are advancing the use of data and technology.

Supporting Our Customers

The MyAirProducts℠ mobile application and web portal is a one-stop shop for all of our customers’ needs, enabling them to track their cylinder inventory, find key documents, and place orders online. We also offer Air Products Process Intelligence, which employs sensors and wireless communications technology that enables customers to monitor key process parameters, helping them improve efficiency, lower gas use, and reduce downtime in their operations.

Improving Our Performance

We are using novel computational and digital technologies—such as advanced modeling; data sciences including, Machine Learning; and real-time optimization—to drive step-change productivity. For example, we monitor ~400 operating plants around the world through our internally developed and patented ProcessMD™ platform. Using advanced analytics and modeling, ProcessMD enables us to operate efficiently in real time, reduce power consumption, increase production, and reduce vent losses. We also use monitoring and analytics on the road to enhance the safety and performance of our drivers.

Improving Our Performance

We are using novel computational and digital technologies—such as advanced modeling; data sciences including, Machine Learning; and real-time optimization—to drive step-change productivity. For example, we monitor ~400 operating plants around the world through our internally developed and patented ProcessMD™ platform. Using advanced analytics and modeling, ProcessMD enables us to operate efficiently in real time, reduce power consumption, increase production, and reduce vent losses. We also use monitoring and analytics on the road to enhance the safety and performance of our drivers.

Improving Our Performance

We are using novel computational and digital technologies—such as advanced modeling; data sciences including, Machine Learning; and real-time optimization—to drive step-change productivity. For example, we monitor ~400 operating plants around the world through our internally developed and patented ProcessMD™ platform. Using advanced analytics and modeling, ProcessMD enables us to operate efficiently in real time, reduce power consumption, increase production, and reduce vent losses. We also use monitoring and analytics on the road to enhance the safety and performance of our drivers.

Thailand |

Thailand |